Production Planning

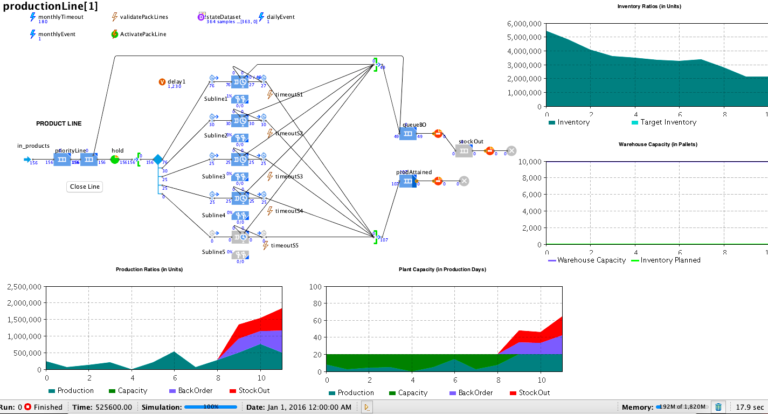

As part of our S&OP planning platform, one of its modules is a Production planning model. This solution gives you the ability to generate a long-term production plan, according to capacity, labor and other production constraints.

Different weekly production plan scenarios, optimized to avoid stock-outs, align inventory levels with safety stocks policies, will be available for your monthly S&OP consensus meetings. Based on the selected 18 rolling Month Demand Forecast.

The solution takes into account all relevant variables from the production process, to find the best production plan that maximizes profitability.

Using a digital twin of the production process, customized to your business, you will have the ability to define different scenarios for the same demand plan and evaluate different outcomes.